Welcome to the Kohler 7000 Series Service Manual, your comprehensive guide for maintaining, troubleshooting, and repairing Kohler engines. This manual is designed to help technicians and owners ensure optimal engine performance, safety, and longevity through detailed procedures and specifications.

Overview of the Kohler 7000 Series Engines

The Kohler 7000 Series engines are a line of high-performance, gasoline-powered engines designed for residential and commercial outdoor power equipment. These engines are known for their reliability, durability, and fuel efficiency, making them a popular choice for lawn tractors, generators, and other small machinery. The series includes models such as the KT715, KT725, and KT730, each offering varying power outputs to suit different applications. Built with a robust overhead valve (OHV) design and cast-iron cylinder sleeves, these engines provide consistent performance and long service life. They are also equipped with advanced features like automatic compression release and a forged steel crankshaft, ensuring smooth operation under demanding conditions.

Importance of Regular Maintenance and Service

Regular maintenance is essential for ensuring the optimal performance, reliability, and longevity of Kohler 7000 Series engines. Proper servicing helps prevent unexpected breakdowns, reduces repair costs, and maintains warranty coverage. By following the recommended maintenance schedule, you can ensure the engine operates efficiently, delivering consistent power and fuel economy. Key tasks include oil changes, air filter cleaning, and fuel system checks. Neglecting maintenance can lead to premature wear, reduced performance, and potential engine damage. Always refer to the service manual for specific procedures and guidelines to keep your engine in peak condition and extend its service life effectively.

Structure and Content of the Service Manual

The Kohler 7000 Series Service Manual is organized into clear sections, providing easy access to essential information. It begins with an introduction, followed by safety precautions, maintenance schedules, and detailed repair procedures. The manual includes technical specifications, troubleshooting guides, and diagrams to aid in diagnostics and repairs. Each section is designed to address specific aspects of engine service, ensuring technicians and owners can quickly find relevant information. The manual also covers tools and equipment needed for maintenance and repair, as well as environmental considerations and warranty details. This comprehensive structure ensures that all aspects of engine care are thoroughly covered, making it an indispensable resource for anyone working with the Kohler 7000 Series engines.

Safety Precautions and Guidelines

Always stop the engine and ensure it is level before performing any maintenance or service. Wear personal protective equipment (PPE) and use proper tools to avoid injuries. Follow all safety guidelines and manufacturer recommendations to ensure safe and effective service procedures.

General Safety Tips for Engine Service

Always ensure the engine is stopped and level before performing any maintenance or service. Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a face mask. Disconnect the battery and relieve fuel pressure to prevent accidental start-ups or fluid leaks. Use jack stands for added safety when working under the engine. Keep the work area well-ventilated to avoid inhaling harmful fumes. Avoid wearing loose clothing that could get caught in moving parts. Never smoke or use open flames near flammable materials. Follow all manufacturer guidelines and warnings provided in the manual. Regularly inspect tools and equipment for damage or wear. Stay alert and avoid fatigue during service procedures for optimal safety and accuracy.

Personal Protective Equipment (PPE) Requirements

- Safety Glasses/Goggles: Essential for protecting eyes from debris, chemicals, or accidental fluid sprays during maintenance.

- Heat-Resistant Gloves: Necessary for handling hot engine components and ensuring a secure grip on tools and parts.

- Face Mask: Recommended to prevent inhalation of dust, fumes, or particles when working with engine components or cleaning parts.

- Steel-Toe Boots: Important for protecting feet from heavy tools, falling objects, or compression injuries in the workspace.

- Long Sleeves and Pants: Advised to protect skin from cuts, abrasions, or exposure to hazardous materials.

Always wear appropriate PPE to minimize risks and ensure a safe working environment when servicing the Kohler 7000 Series engines.

Pre-Service Checks and Engine Preparation

- Stop the Engine: Ensure the engine is completely stopped before starting any service to prevent accidents or injuries.

- Allow Cooling: Let the engine cool down to avoid burns or damage from hot components.

- Inspect the Area: Clear the workspace of flammable materials and ensure good ventilation.

- Check Warranty: Verify warranty coverage and adhere to manufacturer guidelines to maintain validity.

- Level Ground: Ensure the engine is on a level surface for accurate measurements and safe servicing.

- Disconnect Battery: Remove the negative battery cable to prevent accidental starts.

- Drain Fuel: Safely drain fuel if necessary, following proper disposal procedures.

- Inspect for Damage: Look for signs of wear or damage before proceeding with maintenance.

These pre-service checks ensure a safe and efficient maintenance process for the Kohler 7000 Series engine.

Maintenance Schedule and Procedures

Regular maintenance ensures optimal performance and longevity; Follow the recommended schedule for oil changes, filter replacements, and inspections. Adhere to the manual for detailed procedures.

Daily and Pre-Operation Checks

Before starting your Kohler 7000 Series engine, perform daily and pre-operation checks to ensure optimal performance and safety. Begin by verifying the oil level, fuel level, and coolant level, ensuring they meet the recommended specifications. Inspect the air filter for cleanliness and the fuel system for any leaks or blockages. Check the cooling system for proper function and ensure all belts and hoses are secure. Additionally, inspect the spark plug and ignition system for any signs of wear. Always refer to the service manual for detailed guidelines and safety precautions. Regular checks help prevent unexpected issues and ensure reliable engine operation. Proper preparation is key to maintaining engine health and longevity.

Oil Change and Lubrication Procedures

Regular oil changes are essential for maintaining the longevity and performance of your Kohler 7000 Series engine. Use high-quality oil that meets the specifications outlined in the manual, such as Kohler-provided 10W-30 or 10W-40 synthetic blend oil. Before starting, ensure the engine is warm and parked on a level surface. Drain the old oil into a pan, then replace the oil filter with a genuine Kohler filter. Refill the engine with the recommended oil capacity, typically around 2 quarts, depending on the model. Check the oil level using the dipstick and top it off if necessary. Proper lubrication ensures smooth operation and prevents premature wear. Always dispose of used oil and filters responsibly.

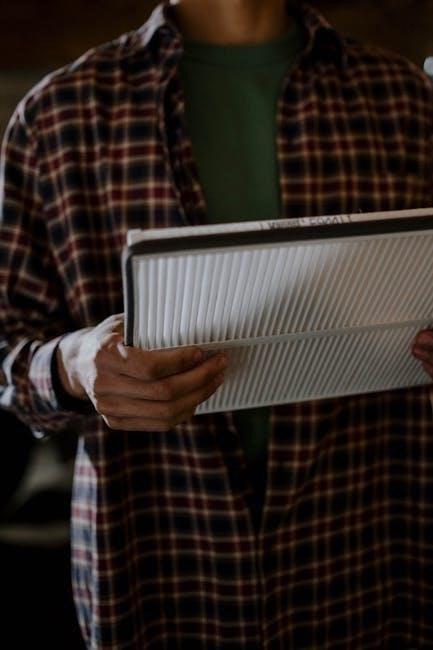

Air Filter Cleaning and Replacement

Regular air filter maintenance is crucial for ensuring optimal performance and longevity of the Kohler 7000 Series engines. A dirty or clogged air filter can lead to reduced power, decreased fuel efficiency, and potential engine damage. To clean the air filter, remove it from the housing and gently tap it to dislodge loose debris. For heavier dirt buildup, use compressed air or a soft-bristle brush. Replace the air filter every 100-200 hours of operation or as specified in the service manual. Always use genuine Kohler replacement parts to maintain warranty coverage and performance standards. Proper disposal of used air filters is recommended to minimize environmental impact.

Fuel System Maintenance and Recommendations

Regular fuel system maintenance is crucial for optimal performance and longevity of the Kohler 7000 Series engines. Always use high-quality fuel that meets the specifications outlined in the manual. Add Kohler PRO Series fuel treatment or an equivalent to the fuel tank to prevent corrosion and maintain fuel system health. Inspect fuel lines and connections regularly for leaks or damage. Clean or replace the fuel filter as specified to ensure proper fuel flow. Drain old fuel and replace it with fresh, properly stabilized fuel before extended storage. Follow recommended procedures for fuel system bleeding to remove air pockets. Proper fuel maintenance ensures efficient engine operation and reduces the risk of premature wear. Always refer to the manual for specific recommendations tailored to your engine model.

Engine Specifications and Technical Details

The Kohler 7000 Series engines are known for their high performance and durability. Key specifications include a range of horsepower options and advanced fuel systems for efficiency.

Key Features of the Kohler 7000 Series Engines

The Kohler 7000 Series engines are renowned for their efficiency, durability, and reliability. These engines feature advanced combustion technology, ensuring optimal fuel efficiency and reduced emissions. They are designed with a robust cooling system to maintain consistent performance under varying loads. The series includes models like the KT715, KT725, and KT730, each offering unique specifications to cater to different applications. With a focus on ease of maintenance, these engines incorporate accessible components for routine service. Additionally, Kohler recommends using their Pro Series fuel treatment to enhance engine longevity and performance. These features make the 7000 Series a top choice for professionals seeking dependable power solutions.

Engine Model Designations and Configurations

Kohler 7000 Series engines are available in various configurations to suit different applications. The model designations, such as KT715, KT725, and KT730, indicate specific specifications like displacement and horsepower. These engines are designed for both industrial and commercial use, offering reliable power solutions. The numerical designations provide clarity on engine capabilities, ensuring users can select the right model for their needs. Configurations include options for gasoline or diesel fuel, as well as different emissions standards. The series also features customizable settings to adapt to various operating conditions. Proper understanding of these designations is crucial for ordering correct parts and ensuring optimal performance. Always refer to the service manual for detailed specifications and maintenance guidance.

Performance Ratings and Specifications

The Kohler 7000 Series engines deliver exceptional power and efficiency, with horsepower ratings ranging from 22 to 26 HP. These engines are designed for heavy-duty applications, offering high torque output for consistent performance. The series features both gasoline and diesel configurations, ensuring versatility for various operating conditions. Key specifications include displacement, compression ratio, and fuel system details, which are outlined in the service manual. The engines are also engineered to meet stringent emissions standards, making them environmentally friendly. Performance ratings vary slightly across models like KT715, KT725, and KT730, but all share a reputation for reliability and durability. Always consult the manual for precise specifications tailored to your engine model.

Tools and Aids for Service and Repair

The Kohler 7000 Series requires specific tools like wrenches, diagnostic equipment, and specialized gadgets for efficient servicing. Ensure safety and precision with the right aids for repairs.

Essential Tools for Kohler 7000 Series Maintenance

Proper tools are crucial for effective maintenance of the Kohler 7000 Series engines. Essential tools include a torque wrench for precise bolt tightening, a multimeter for electrical system diagnostics, and a compression tester to evaluate engine performance. A set of metric and SAE wrenches and sockets is also necessary for various adjustments and repairs. Additionally, a filter wrench simplifies oil and fuel filter replacements. Specialized tools like an offset wrench (for K and M Series) may be required for specific tasks. Always ensure tools are in good condition to avoid damage to engine components. Refer to the manual for a detailed list of recommended tools and equipment for optimal servicing. Proper tools ensure safety and efficiency during maintenance procedures.

Diagnostic Tools and Equipment

Diagnostic tools are vital for identifying and resolving issues in the Kohler 7000 Series engines. A multimeter is essential for testing electrical circuits, while a compression tester helps assess engine performance and detect internal issues. Fuel pressure testers are critical for diagnosing fuel system problems, ensuring proper flow and pressure. Additionally, a scan tool or diagnostic software may be used to retrieve error codes and monitor engine parameters. These tools enable technicians to pinpoint faults accurately and efficiently. Always use manufacturer-recommended diagnostic equipment to ensure reliability and compatibility with the Kohler 7000 Series. Proper diagnostics are the first step toward effective troubleshooting and maintenance, preventing minor issues from becoming major repairs.

Specialized Tools for Specific Repairs

Specialized tools are essential for certain repairs on the Kohler 7000 Series engines. For engine rebuilds, tools like piston ring compressors and bearing pullers are necessary. Fuel system repairs may require a fuel injector tester. Adjustable wrenches and torque wrenches are crucial for precise adjustments. Always use Kohler-recommended tools for tasks like valve adjustments to ensure compatibility and safety. These tools help prevent engine damage and ensure professional-grade repairs. Proper tool usage is vital for maintaining engine integrity and performance. Always refer to the service manual for specific tool requirements. Using the right tools ensures accurate and efficient repairs, preserving the longevity of your Kohler 7000 Series engine.

Troubleshooting Common Issues

This section provides guidance on diagnosing and resolving common problems with the Kohler 7000 Series engines, covering issues like engine overheating, low power output, and fuel system faults.

Identifying and Diagnosing Engine Problems

Diagnosing engine issues in the Kohler 7000 Series begins with observing symptoms like unusual noises, reduced performance, or warning lights. Always stop the engine and ensure it is level before inspection. Check for common issues such as overheating, low oil levels, or faulty spark plugs. Use diagnostic tools like code readers or compression testers to identify specific faults. Refer to the troubleshooting section of the manual for detailed guidance on interpreting symptoms and error codes. Proper diagnosis is crucial for effective repairs and ensures the engine operates safely and efficiently. Always consult the service manual for accurate procedures and recommendations. Early detection prevents major damage.

Common Faults and Their Solutions

The Kohler 7000 Series engines may experience common issues such as low oil pressure, overheating, or poor starting performance. Low oil levels or dirty filters often cause these problems. Regular maintenance, like oil changes and filter replacements, can prevent such faults. Faulty spark plugs or ignition coils may also lead to engine misfires. Replace these components as needed and ensure proper connections. Cooling system issues, such as blocked radiators or faulty thermostats, can cause overheating. Clean or replace these parts as required. Always refer to the service manual for specific diagnostic steps and repair procedures to address these issues effectively and maintain engine performance. Timely fixes prevent costly repairs.

Engine Overheating and Cooling System Issues

Engine overheating is a common issue that can lead to costly damage if not addressed promptly. Causes include low coolant levels, blocked radiators, or faulty thermostats. Regularly inspect the cooling system for debris or corrosion. Ensure the radiator is clean and free of obstructions. Check coolant levels and top up with a Kohler-approved coolant mixture. Replace the thermostat if it fails to open properly. Avoid using unapproved coolants, as they may damage engine components. If overheating persists, consult the service manual for detailed diagnostic steps. Always allow the engine to cool before performing repairs. Proper maintenance of the cooling system is essential for preventing overheating and ensuring long-term engine health.

Repair and Replacement Procedures

Follow detailed step-by-step guides for repairs, including cylinder head replacements and crankshaft inspections. Use essential tools like offset wrenches for precise adjustments. Adhere to manufacturer guidelines to ensure durability and prevent further issues.

Step-by-Step Guide for Common Repairs

For common repairs on the Kohler 7000 Series engines, start by gathering essential tools and diagnostic equipment. Always ensure the engine is stopped and level before beginning. Identify the issue using diagnostic tools, then follow the manual’s specific repair procedures. For air filter replacements, remove the housing, inspect for debris, and install a new filter. Spark plug replacement requires a socket wrench; ensure proper torque specifications. Fuel system repairs may involve cleaning or replacing injectors. After completing repairs, test the engine under load to confirm functionality. Always refer to the service manual for detailed instructions and safety guidelines to avoid further damage or safety risks.

Replacement of Wearable Parts

Regular replacement of wearable parts is essential for maintaining the performance and longevity of your Kohler 7000 Series engine. Common wearable parts include piston rings, valves, spark plugs, and belts. Always use genuine Kohler replacement parts to ensure compatibility and reliability. Before starting any replacement, consult the service manual for specific instructions and torque specifications. Proper tools, such as wrenches and pullers, are required to avoid damaging components. Cleanliness is crucial during replacement to prevent contamination. After installation, test the engine under load to ensure proper operation. Keep a record of replacements for future reference and to stay on track with maintenance schedules. Always follow safety guidelines to avoid accidents.

Engine Rebuild and Major Overhaul Procedures

Engine rebuild and major overhaul procedures for the Kohler 7000 Series require precision and adherence to manufacturer guidelines. These processes are typically performed when the engine exhibits significant wear or damage. Specialized tools, such as piston ring compressors and bearing pullers, are essential for disassembly and reassembly. Genuine Kohler parts must be used to ensure compatibility and performance. The service manual provides detailed step-by-step instructions, including torque specifications and alignment procedures. Only trained technicians should attempt a major overhaul to avoid further damage. Proper testing, such as compression checks and oil pressure verification, is critical after completion. Keep detailed records of the overhaul for future reference and warranty purposes.

Warranty and Support Information

The Kohler 7000 Series is backed by a comprehensive warranty program, ensuring coverage for parts and labor under specified conditions. For support, contact Kohler customer service or visit authorized service centers for assistance. Online resources, including manuals and FAQs, are also available to address common inquiries and troubleshooting needs. Warranty details and support options are outlined in the service manual and on the KohlerEngines.com website.

Understanding the Kohler Warranty Coverage

The Kohler 7000 Series engines are backed by a comprehensive warranty program designed to protect your investment. The warranty coverage typically includes parts and labor for defects in materials and workmanship during the specified period. Registration of your engine is often required to activate the warranty, and proper maintenance as outlined in the service manual is essential to ensure coverage remains valid. The warranty period varies depending on the model and usage, with details provided in the warranty card or on the KohlerEngines.com website. Understanding the terms and conditions of your warranty helps you maintain compliance and ensures uninterrupted support for your engine.

Contacting Customer Support and Service Centers

For assistance with your Kohler 7000 Series engine, contact customer support through the official KohlerEngines.com website. Use the “Contact Us” section for inquiries, parts orders, or technical support. You can also reach local service centers via phone or email for personalized help. Ensure to have your engine model number, such as KT715, ready for efficient service. Kohler’s support team is available to address warranty claims, troubleshooting, and maintenance questions. Visit authorized dealers for genuine parts and expert advice. Online resources, including manuals and FAQs, are also accessible on the Kohler website for quick solutions. Rehlko, now representing Kohler Engines, offers additional support and guarantees for your engine needs.

Online Resources and Technical Assistance

For the Kohler 7000 Series, extensive online resources are available to support maintenance and repair. Visit the official KohlerEngines.com for downloadable PDF service manuals, parts diagrams, and troubleshooting guides. The website also features a dedicated section for the 7000 Series, including model-specific documentation like the KT715 service manual. Additional resources such as FAQs, diagnostic tools, and maintenance tips are accessible to help users resolve issues quickly. Registered users can access exclusive content, including detailed repair procedures and warranty information. For further assistance, utilize the “Contact Us” portal or visit authorized Kohler service centers for personalized support and genuine parts. These online tools ensure efficient problem-solving and optimal engine performance.

Environmental and Fuel Considerations

Adhere to eco-friendly practices by using recommended fuel types and additives for the Kohler 7000 Series. Proper disposal of hazardous materials ensures environmental compliance and sustainability.

Eco-Friendly Practices for Engine Maintenance

Adhering to eco-friendly practices during engine maintenance is crucial for reducing environmental impact. Always use the recommended fuel types and additives to minimize emissions and ensure optimal performance. Proper disposal of hazardous materials, such as used oil and filters, is essential to prevent contamination. Regularly inspect and maintain the cooling system to avoid leaks and optimize efficiency. Use energy-efficient tools and follow the recommended maintenance schedule to reduce unnecessary fuel consumption. Additionally, consider using biodegradable cleaners for engine cleaning. By following these practices, you contribute to environmental sustainability while ensuring the longevity and health of your Kohler 7000 Series engine.

Recommended Fuel Types and Additives

For optimal performance of your Kohler 7000 Series engine, use clean, fresh gasoline with a minimum octane rating of 87. Avoid using ethanol-blended fuels, as they can cause phase separation and damage engine components. Add Kohler PRO Series fuel treatment or an equivalent to the fuel tank to prevent corrosion, stabilize fuel, and maintain the health of the fuel system; Regular use of these additives ensures consistent engine operation and protects against wear. Always follow the manufacturer’s guidelines for fuel and additive usage to maintain warranty coverage and engine longevity. Proper fuel management is essential for both performance and environmental sustainability.

Proper Disposal of Hazardous Materials

Proper disposal of hazardous materials is crucial to protect the environment and comply with regulations. Always follow local, state, and federal guidelines for disposing of engine-related waste, such as used oil, filters, and batteries. Ensure all hazardous materials are neutralized or contained before disposal. Use authorized recycling centers or facilities equipped to handle automotive and industrial waste. Never dispose of hazardous materials in regular trash or drain them into sewers or waterways. Refer to the Kohler 7000 Series Service Manual for specific instructions on handling and disposing of engine fluids, filters, and other potentially hazardous components safely and responsibly.

Regular maintenance and adherence to the Kohler 7000 Series Service Manual ensure engine longevity and performance. Always follow safety guidelines and use genuine parts for optimal results.

Best Practices for Long-Term Engine Health

Regular inspections and adherence to the maintenance schedule are crucial for ensuring the longevity of your Kohler 7000 Series engine. Always use genuine Kohler parts to maintain performance and reliability. Keep the engine clean, and ensure proper ventilation to prevent overheating. Monitor fuel quality and use recommended additives to avoid contamination. Store the engine in a dry, secure location when not in use. Follow all safety guidelines and manufacturer recommendations to prevent damage. Train users and technicians on proper operation and maintenance techniques. By following these best practices, you can maximize efficiency, reduce wear, and extend the lifespan of your engine.

Staying Updated with the Latest Service Manual Revisions

To ensure optimal performance and compliance with the latest standards, it is essential to stay updated with the newest revisions of the Kohler 7000 Series Service Manual. Regularly visit the official Kohler website or authorized service centers for updates. Subscribe to notifications or newsletters to receive alerts about new manual releases. Updated manuals often include improved procedures, new diagnostic tools, and enhanced troubleshooting guides. Keeping your manual current ensures access to the latest technical advancements and safety protocols. Referencing outdated information can lead to suboptimal maintenance and potential safety hazards. Always verify the revision date of your manual and update it as needed to maintain reliability and engine longevity.

Importance of Following Manufacturer Guidelines

Following the guidelines outlined in the Kohler 7000 Series Service Manual is crucial for ensuring the safety, performance, and longevity of your engine. Manufacturer recommendations are based on extensive testing and design expertise, helping to prevent potential damage and ensure reliability. Adhering to these guidelines also guarantees compliance with warranty terms, as deviations may void coverage. Proper maintenance and repair practices, as specified, minimize risks of premature wear and unexpected failures. By adhering to these instructions, you can maintain optimal engine health, reduce repair costs, and ensure environmental compliance. Always refer to the latest manual revisions for updated procedures and specifications to keep your engine operating at its best.